|

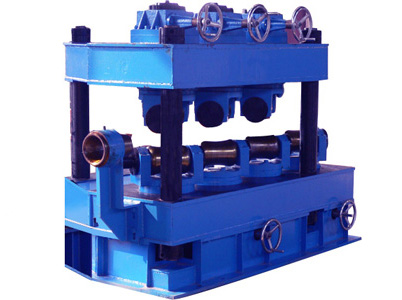

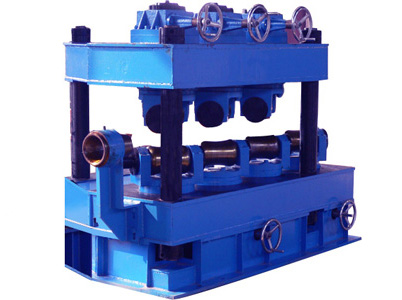

Straightening machine

Introduction of the straightening machine

Straightening machines have been built with various methods of driving the rolls. Some machines have a separate drive motor for each roll, whereas the majority of modern machines usually use 2 drive motors, one motor for the top set of rolls and one for the bottom rolls. Regardless of the way the rolls are driven it is important that all rolls revolve at the same speed within about 1 to 2 rpm at maximum machine speed. In addition it is usual for the manufacture to build in an electronic load sharing system to ensure that the power needed to straighten is shared equally between the driving motors. Each time the rolls are changed a check of roll rpm and motor loading should be carried out.

If the rolls are not revolving at highly similar speeds, under load, tube straightness will be poor, roll wear will be rapid and under high straightening loads the motors may run out of power and stall.

Pipe straightening machine Steel pipe straightening machine Steel tube straightening machine Tube straightening machine

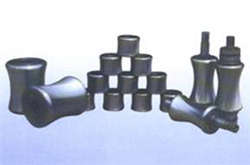

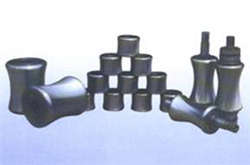

Introduction of the rolls

A certain black art and mystery surrounds tube and pipe rotary straightening machines. Like all machinery, the various components and systems join together to form the working straightener, however the heart of a tube straightener, is the set of work rolls, specially contoured to enable the machine to straighten a range of different tube diameters.

When a new straightener is put into service, for the first period of operation, the freshly trained personnel concerned with operating and maintenance are well versed in using and caring for the machine. But as time passes, recessions and good times come and go, but a well constructed straightening machine lives through it all giving 2, 3 or even 4 decades of useful life. Throughout its life many personnel changes will occur and the techniques of operation will also change, usually for the worse, until a customer complains of poor tube straightness, barber pole marks along the tube and, or serious mechanical defects in the tube material.

With the machine in reasonable mechanical condition and roll drive systems operating correctly, most problems can be eliminated by ensuring that the rolls are in good condition, properly aligned in the machine and then correctly setup by a well trained operator. Straightening machine is the finishing equipment for the high frequency welded tube mill line, which is used to straighten the steel tubes , eliminate the stress and bend the steel tube after forming and welding.

Roller Roll profile

Introduction of the straightening machine

Straightening machines have been built with various methods of driving the rolls. Some machines have a separate drive motor for each roll, whereas the majority of modern machines usually use 2 drive motors, one motor for the top set of rolls and one for the bottom rolls. Regardless of the way the rolls are driven it is important that all rolls revolve at the same speed within about 1 to 2 rpm at maximum machine speed. In addition it is usual for the manufacture to build in an electronic load sharing system to ensure that the power needed to straighten is shared equally between the driving motors. Each time the rolls are changed a check of roll rpm and motor loading should be carried out.

If the rolls are not revolving at highly similar speeds, under load, tube straightness will be poor, roll wear will be rapid and under high straightening loads the motors may run out of power and stall.

Pipe straightening machine Steel pipe straightening machine Steel tube straightening machine Tube straightening machine

Model |

Tube |

Working speed (m/min) |

Roll distance (mm) |

Roller QTY |

Roll material |

Motor power(kw) |

Machine size (mm)(L*W*H) |

Machine weight(kg) |

||

Dia.(mm) |

Thickness (mm) |

Yield strength (N/mm2) |

||||||||

WTM-TZ-3/12 |

Φ3-Φ12 |

0.4-4 |

392 |

23 |

150 |

---- |

9Cr2Mo |

0.75*2 |

1375*660*1050 |

550 |

WTM-TZ-5/20 |

Φ5-Φ20 |

0.5-4 |

392 |

32.5 |

190 |

---- |

1.5*2 |

1275*890*1405 |

1050 |

|

WTM-TZ-6/30 |

Φ6-Φ30 |

0.8-5 |

420 |

30.5 |

280 |

---- |

5.5*2 |

2720*1480*1710 |

4300 |

|

WTM-TZ-12/50 |

Φ12-Φ50 |

1-3.5 |

---- |

60/120 |

---- |

6 |

7.2*2 |

2950*1280*1130 |

---- |

|

WTM-TZ-15/60 |

Φ15-Φ60 |

1.2-4.5 |

---- |

35/70 |

10-110 |

---- |

14/22*2 |

3230*2215*1555 |

5880 |

|

WTM-TZ-20/76 |

Φ20-Φ76 |

1-4.5 |

---- |

30/68 |

---- |

7 |

15*2 |

3090*2058*1400 |

---- |

|

WTM-TZ-30/90 |

Φ30-Φ90 |

1.5-5 |

---- |

30/68 |

---- |

7 |

15*2 |

3600*2200*1500 |

---- |

|

WTM-TZ-48/114 |

Φ48-Φ114 |

2.0-5.5 |

---- |

30/68 |

---- |

7 |

18.5*2 |

4827*2575*1800 |

---- |

|

WTM-TZ-50/120 |

Φ50-Φ120 |

---- |

---- |

26 |

---- |

9 |

45*2 |

3800*1400*2350 |

---- |

|

WTM-TZ-60/160 |

Φ60-Φ160 |

---- |

---- |

25 |

---- |

7 |

55*2 |

3100*1500*2450 |

---- |

|

Introduction of the rolls

A certain black art and mystery surrounds tube and pipe rotary straightening machines. Like all machinery, the various components and systems join together to form the working straightener, however the heart of a tube straightener, is the set of work rolls, specially contoured to enable the machine to straighten a range of different tube diameters.

When a new straightener is put into service, for the first period of operation, the freshly trained personnel concerned with operating and maintenance are well versed in using and caring for the machine. But as time passes, recessions and good times come and go, but a well constructed straightening machine lives through it all giving 2, 3 or even 4 decades of useful life. Throughout its life many personnel changes will occur and the techniques of operation will also change, usually for the worse, until a customer complains of poor tube straightness, barber pole marks along the tube and, or serious mechanical defects in the tube material.

With the machine in reasonable mechanical condition and roll drive systems operating correctly, most problems can be eliminated by ensuring that the rolls are in good condition, properly aligned in the machine and then correctly setup by a well trained operator. Straightening machine is the finishing equipment for the high frequency welded tube mill line, which is used to straighten the steel tubes , eliminate the stress and bend the steel tube after forming and welding.

Roller Roll profile